The primary application include throttle control modules, flap/slat position controls, landing gear controls, bay door control and position indication, and in other similar functions where a rotary control and/or position monitoring are required.

The uniqueness of our products is in the air design for weight and size and the ease of adjustment of the cam mechanisms. The patented cam mechanisms on each individual stack allow to accurately set desired angles even under conditions of corresponding shad linkage variations, especially when working with detentes.

For switching purposes, we use exclusively Honeywell micro-switches only. Low loads are handled with application of golf contacts. Reliability is a high reaching millions of cycles for mechanical life and hundreds of thousands for electrical life.

We design and manufacture our own gear boxes in combination with our cam switches and procured synchros and/or potentiometeres. We make cable assemblies and are qualified in Mil-Std-2000 soldering and harness manufacturing procedures. Our statistical process control system had been approved and certified by Lockheed Martin.

A Low Torque, Precision Component with Adjustable Snap-Action Switching

- Adjusts to any desired switch dwell angle from 3° to 357 ° of shaft rotation.

- Switch settings infinitely adjustable with respect to shaft.

- Switch setting independent of other switches in stack

- Switching angles cane be set and locked in seconds

- Adjustments can be made while shaft is either stationary or rotating

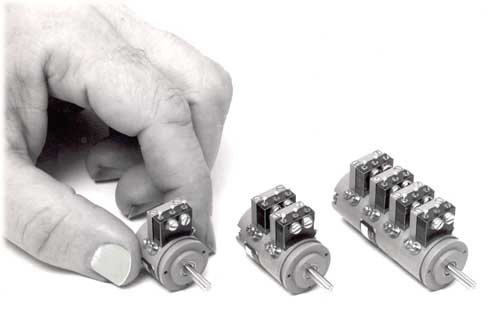

- Only 1-1/16" diameter; equivalent of BuOrd Size 11.

The PMC Model CS 402 Cam Switch combines in a compact 1-1/16" diameter unit all the functions of a conventional plate cam, cam follower and snap-action switch. External screwdriver adjustments permit rapid setting of any desired switch make angle. Designed for timing, indication, control, computation and other applications where snap action switching is required, it permits the instrument and servo designer to meet specific application requirements through use of a single component that can be mounted in a gear assembly in a manner similar to synchros, potentiometers and other rotating shaft components. Because the CS 402 Cam Switch replaces conventional cam mechanisms, independently mounted switches and their associated hardware, it provides significant savings in design, fabrication and assembly time. Its small size permits significant improvements in miniaturization of the end product.

Adjustment of the CS 402 Cam Switch can be accomplished rapidly and precisely while the shaft is either stationary or rotating, by means of two external adjusting screws, and can be completed within seconds. As a result, it provides a unique means for ‘trimming-in’ required performance in production or during equipment maintenance. Conveniently located locking screws maintain switch settings underall conditions of shock and vibration encountered by military equipment. Model CS 402 Cam Switches incorporate standard type SPDT, subminiature, snap switches and are available as single-switch units, or as multi-ganged types with as many as 10 switches. Both single and multi-stack types can be supplied with double-ended shaft for mounting dial or indicator. All types meet applicable requirements of MIL-E-5400. Complete mechanical and electrical specifications are given below.

| Part No. | No. Of Switches | Dim. "L" (In. Max.) | Inertia (OZ. IN. Sec. ²) | WT. (OZ.) |

| CS402-1 | 1 | .800 | 0.6x10-5 | 1.4 |

| CS402-2 | 2 | 1.300 | 1.2x10-5 | 2.1 |

| CS402-3 | 3 | 1.800 | 1.8x10-5 | 2.8 |

| CS402-4 | 4 | 2.300 | 2.5x10-5 | 3.5 |

| CS402-5 | 5 | 2.800 | 3.1x10-5 | 4.3 |

| CS402-6 | 6 | 3.300 | 3.7x10-5 | 5.0 |

| CS402-7 | 7 | 3.800 | 4.3x10-5 | 5.7 |

| CS402-8 | 8 | 4.300 | 4.9x10-5 | 6.5 |

| CS402-9 | 9 | 4.800 | 5.5 x10-5 | 7.2 |

| CS402-10 | 10 | 5.300 | 6.1x10-5 | 8.0 |

SPECIFICATIONS:

Electrical Ratings:

115/230 vac 5 amp, inductive and resistive

30 vdc resistive, sea level 5.0 amp

resistive, 50,000 ft 5.0 amp

inductive, sea level 3.0 amp

inductive, 50,000 ft 2.5 amp

Max. Inrush 24 amp

Mechanical Data:

Shaft rotates on precision ball bearings

Shaft End Play 003 in., max.

Shaft Pilot Run out 001 in., max., T.I.R.

Temperature Range -65ºF to +250ºF

Make-Break Differential 1.5º max.

Operating Torque 1.5 oz.-in., max., per switch (see note)

NOTE: peak torque occurs at switch actuation. With all switches in a multi-switch unit set to identical on-off positions, the total maximum torque will not exceed n x 1.5 oz-in., (where n is the number of switches in the stack). With different switch settings the total maximum torque may be as low as 0.5 x n x 1.5 oz-in., depending upon the specific on-off settings.

VARIATIONS FOR PARTICULAR REQUIREMENTS

Precision Mechanisms Corporations will be pleased to quote on variations for the CS 402 Cam Switch for special requirements. Readily available variations include:

- non-standard shaft extension

- double-ended shaft extension

- ultra low differential switches

- multi-switch units mounted in gear train mechanisms for specific switching functions, with or without motor drive

Sub-Miniature Adjustable Cam Switches

Model CS 601 - Bulletin 109

- Switch dwell angles continuously adjustable from 3º to 357º

- Operating sector infinitely adjustable to any shaft position.

- External screwdriver adjustment of switching angles.

- Can be set while shaft is stationary or rotating.

- Switch settings independent of other switches in stack.

- Only ¾” diameter; equivalent to BuOrd Size 8.

Model CS 601 Adjustable Cam Switch utilizes PMC’s patented* cam switch design in a sub-miniature assembly developed specifically for airborne, space vehicle and other applications where size and weight are critical. It incorporates in a single BuOrd Size 8 end-mounted unit all the functions of a conventional plate cam, cam follower and snap-action switch, eliminating the need for separately-mounted cam mechanisms and switches and their associated hardware.

Switch “on” and “off” points can be quickly set by means of external screws while the shaft is either stationary or in motion. Dwell angles as small as 3º or as great as 357º can be set for either closed or open circuits, depending upon choice of switch terminals. External locking screws maintain switch settings under all conditions of shock and vibration encountered in military and/or commercial equipment.

Model CS 601 Adjustable Cam Switches incorporate standard type SPDT sub-miniature snap switches and are available as single switch units or in ganged assemblies with as many as eight independently-adjustable switches. Both single- and multi-switch types can be supplied with optional shaft extensions or double-ended shafts. All models meet the applicable requirements of Ml L-E-5400.

* Pat. No. 3,060,286

| Part No. | No. Of Switches |

Dim. "L" (In., Max.) |

Inertia (OZ. IN. SEC.2) |

WT. (OZ.) |

| CS601-1 | 1 | .730 | 2.0x10-6 | 0.7 |

| CS601-2 | 2 | 1.167 | 3.7x10-6 | 1.1 |

| CS601-3 | 3 | 1.604 | 5.5x10-6 | 1.4 |

| CS601-4 | 4 | 2.041 | 7.2x10-6 | 1.8 |

| CS601-5 | 5 | 2.478 | 9.0x10-6 | 2.1 |

| CS601-6 | 6 | 2.915 | 10.7x10-6 | 2.5 |

| CS601-7 | 7 | 3.352 | 12.5x10-6 | 2.8 |

| CS601-8 | 8 | 3.789 | 14.2x10-6 | 3.2 |

SPECIFICATIONS:

Electrical Ratings:

115/230 vac 7 amp, inductive and resistive 28 vdc

resistive, sea level 7.0 amp

resistive, 50,000 ft . . .7.0 amp

inductive, sea level 4.0 amp

inductive, 50,000 ft 2.5 amp

Max. Inrush 24 amp

Mechanical Data:

Shaft rotates on precision ball bearings

Shaft End Play 003 in., max.

Shaft Pilot Runout 001 in., max., T.I.R.

Temperature Range -65°F to +250° F

Make-Break Differential 1.5º max.

Operating Torque 1.2 oz.-in. max. per switch (see note)

NOTE: peak torque occurs at switch actuation. With all switches in a multi-switch unit set to identical on-off positions, the total maximum torque will not exceed n x 1.2 oz-in., (where n is the number of switches in the stack). With different switch settings the total maximum torque may be as low as 0.3 x n x 1 .2 oz-in., depending upon the specific on-off settings and number of switches.

VARIATIONS FOR PARTICULAR REQUIREMENTS

Precision Mechanisms Corporations will be pleased to quote on variations for the CS 402 Cam Switch for special requirements. Readily available variations include:

• non-standard shaft extension

• double-ended shaft extension

• ultra low differential switches

• multi-switch units mounted in gear train mechanisms for specific switching functions, with or without motor drive