Adjustable In Motion Programming Cam Switches For

• Machine and Process Control

• Sequencing

• Cycling

• Timing

• Counting

•Indication

High - Power Adjustable Cam Switches

The CS 501 Rotating Shaft Cam Switch is a

high-capacity, infinitely adjustable limit and programming switch designed for the control, cycling and sequencing of machine operations. Its patented design combines all the functions of an adjustable plate cam, cam follower and snap-action switch in a single readily-mounted unit. Simple external screwdriver adjustments, which can be made while the shaft is either stationary or rotating, set the on and off points of each switch independently, and provide any desired dwell angle from 5º to 355º Switching positions are indicated precisely by high-resolution dials adjacent to the external adjusting screws, permitting even complex control programs to be set up or changed solely by means of the dial indications.

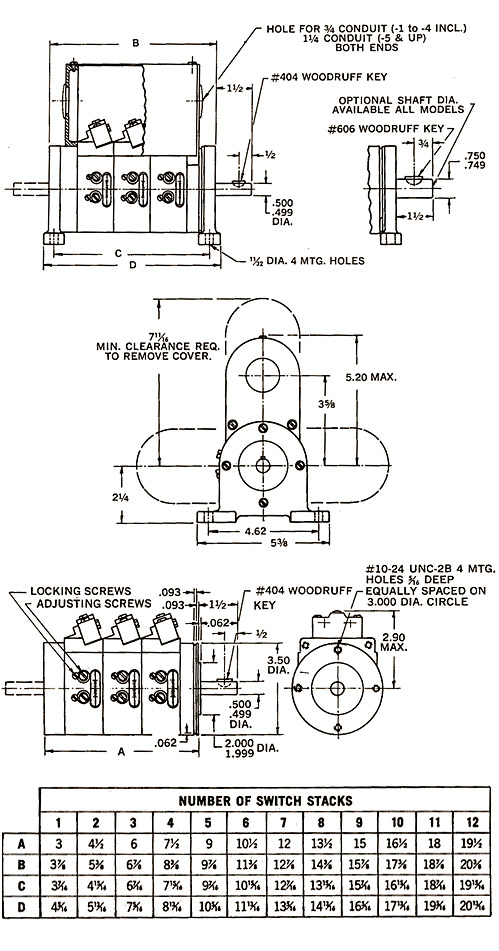

The CS 501 Cam Switch is available in both single or multi-stack units, in end and side-mounting configurations, and with a wide choice of switch types, to meet specific requirements for control and programming of machines of all types. All models can be supplied with switch covers for use in installations where switch wiring must be enclosed.

Patented Design Eliminates Tedious Cam Adjustments

Simplified schematic shows Precision Mechanisms’ patented* design. The two crown gears are superimposed discs with gear teeth at the upturned outer edges for angular adjustment. Each has a slot, as shown, with the degree of overlap of the slots adjustable. The pivoted wheel rides on the flat surface of the inner crown gear and moves downward over the common slotted region. Through the lever arrangements, this downward motion actuates the limit switch. Calibrated dials attached to each crown gear indicate on and off position through a window

501 Specifications

ENVIRONMENTAL:

The actuating plunger of each switch is gasket-ed and the assembly is highly dust resistant. Standard operating range is from -65°F. to +180°F. Materials are corrosion resistant and are of stainless steel or aluminum alloy wherever practical. Models with switch cover conform to NEMA Type I specifications.

ELECTRICAL:

The CS-501 is available with a wide variety of snap-action switches. Contact arrangements include SPDT, DPDT, and two-circuit double break. Almost all high-capacity and special-purpose switches of the major switch manufacturers may be specified. Also, more than one type of switch may be specified in a multi-stack assembly. The switch supplied as standard is a general-purpose unit for handling the high inrush currents of motors, solenoids and tungsten lamps.

Mechanical:

| Rotation: | Bi-directional |

| Max Speed: | 600 RPM at low electrical load. 300 RPM at max electrical load |

| Torque: | 12 oz. in. per switch, with all switches operating at the same point; 12 0z. in. plus 3 0z. in per switch with switches operating at spaced angles |

| Ball Bearings: | Sealed type, lubricated for life |

| Shaft: | Corrosion resistant steel |

| Adjustment Range: | Dwell angles from 5° to 355° at any position with respect to the shaft. |

| Dials: | Marked at 2° intervals |

Switch Characteristics

| Standard Switch: | Switch T | Switch V | Switch U | Switch W |

|---|---|---|---|---|

| Contact Arrangement: | SPDT | SPDT Double Break | SPDT | DPDT |

| Motor Horsepower Rating: | 1 H.P. @ 125 vac 2 H.P. @ 250 vac. |

¾ H.P. @ 125 vac; 1½ H.P. @ 250 vac. |

¼ H.P. @ l25vac ½ H.P. @ 250vac |

⅛ H.P. @ 125 vac ¼ H.P. @ 250 vac. |

| Current: | 20A @ 125, 250 and 480 vac. |

25A @ 125, 250 and 480 vac. |

22A @ 125, 250 and 480 vac. |

10A @ 125 and 250 vac. |

| DC Rating: | 0.5A @ 125 vdc 0.25A @ 230 vdc |

10A @ 125 vdc 0.5A @ 250 vdc |

0.5A @ 125 vdc O.25A @ 250 vdc |

0.3A @ 125 vdc 0.15A @250 vdc |

| Inrush Current: | 75A | 75A | 35A | 30A |

| Make-Break Differential: | ½º at shaft | |||

| Controls two separate circuits. | Provides lowest make-break differential in bi-directional applications | Simultaneously makes and breaks two independent circuits |

Other switches are available for special uses, for example: make-before-break, make-before-make, and pulse-producing snap-action switches. Switches with voltage ratings up to 600 vac can also be supplied. *Specifications subject to change without notice.

Features of the CS 501

External Switching Angle Adjustment:

Switch on and off points can be quickly adjusted by means of external screws while the machine is stationary or in motion. Dwell angles as small as 5º and as great as 355º can be set for either closed or open circuits depending on choice of switch terminals. Locking screws assure that switch settings will be maintained.

Accurate Switch Angle Indicator:

Calibrated dials, marked every 2º and readable to better than 1º, show switch on and off positions. Dials are color-coded gold and silver to match the corresponding adjustment screws, permitting fast, non-ambiguous setting.

Easy Switch Replacement:

Any switch in a single or multi stack assembly can be quickly replaced without disturbing the installation. There is no lengthy downtime or need for spare assemblies.

Pneumatic Switching:

Switch mounting arrangements have been designed to accept air pilot valves in place of the electrical switches, without modification of the cam switch assembly, for direct programming of pneumatically controlled devices. Assemblies may be ordered with air pilot valves or a combination of valves and switches.

Configurations For All Installation Requirements:

The CS 501 Rotating Cam Shaft Switch can be supplied in a choice of end- and side-mounting types, with positioning of adjusting screws, dial windows and switches to suit requirements.

Standard & Optional Styles

(NOTE: Model CS-501 Cam Switches are available in a variety of standard and optional styles to provide choice of mounting, switch and adjustment positions, as illustrated below. The drawings show physical configurations, but are not intended to show the number of switches that can be supplied in each style. For any style selected, the required number of switches should be specified in accordance with the specifying instructions below.)

Thus, in the example given above, the part number describes a side mounted switch, with switches at 12 o'clock and adjustments at 3 o'clock; 12 switches in the assembly, using type T switches, with a 1/2" diameter shaft and a 2.35" rear extension.

Modified Designs For Special Applications Special modifications and adaptations of the CS-501 Cam Switch are available to meet particular requirements. Typical variations include geared assemblies, units with gear heads, special shafts, and special end bells. Precision Mechanisms Corp. welcomes your inquiries and will be pleased to consult with you on special requirements.

INFINITELY ADJUSTABLE MULTI TURN STOPS

- Standard ranges to 40 revolutions.

- Stop rotation is continuously adjustable throughout the full range.

- Range is set by means of a single screw at the end of the unit.

- Flange mounted.

- Meet the applicable environmental and materials sections of MIL-E-5400.

- Corrosion resistant steel and anodized aluminum construction.

- Precision ball bearings.

The LS 100 Series Limit Stops feature extremely simple range setting, low inertia, low starting friction, and large turns capacity.

They eliminate the time, cost, and engineering effort required to design, develop and procure limit stops for each new application.

They enable the designer to consider the limit stop as a component and to design with it in the same manner as with potentiometers, motors, and other standard synchro mounted units.

Changing the full scale stop range to accommodate tolerance variations which occur in normal fabrication and assembly operations.

The large number of turns available allows the stop to be placed at the low torque, high speed, portion of a gear train thereby freeing the low speed gears from large stopping loads.

The simplicity of adjustment and the large number of available turns enables the stop range to be set with extreme precision.

Starting Torque: .04 oz in. max

Shaft Run out: .001 T.I.R. max

Shaft-Pilot Run out: .001 T.I.R. max

| Part No. | Range Revs | Inertia (oz. in. sec2) |

Weight (oz.) |

Torque Rating Oz. In. |

A | D | G | I | P +.0000 -.0008 |

| LS101 | 0-10 | 3.9 x 10-6 | 1.2 | 80 | .062 | .875 | .078 | 1-5/32 | .7500 |

| LS102 | 0-40 | 7.2 x 10-6 | 1.7 | 80 | .062 | .875 | .078 | 1-7/8 | .7500 |

| LS104D | 0-20 | 1.7 x 10-6 | .75 | 30 | .050 | .625 | .062 | 1-15/64 | .3125 |

ADJUSTABLE LIMIT SWITCH & STOP

A Component for Precise Electrical & Mechanical Controls & Indication of Rotation in Gear Trains & Instruments

The LS 302 is an infinitely adjustable limit stop in which electrical end switches are actuated just

before the mechanical stop is reached.

Separate, single pole-double throw, snap-acting switches are provided for clockwise and counter clockwise rotation.

The switch-stop range can be set to any angle between 0 and 25 revolutions by means of a single range-setting screw.

| Switches | SPDT per MS 24547-1 |

| Rating | 5 amps., 250 vac, 30 vdc |

| Make-Break Differential | 30º max. at shaft |

| Actuation Point | 45º (nom.) before stop engagement |

| Range | 0 to 25revolutions |

| Starting Torque | .04 oz. in. max |

| Switching Torque | .35 oz. in |

| Static Rating | 80 oz. in |

| Shaft Inertia | 6 x 10-6 oz. in sec2 |

| Weight | 1.8 oz. |

| Shaft Run out | .001 T.I.R. max |

| Shaft Pilot Run out | .001 T.I.R. max |

General Construction: Corrosion resistant steel and anodized aluminum alloy with Precision Ball Bearings.

Military Specifications: Meets requirements of Mil-E-5400